DEHNIT Earthing Method

Details

For improving and stabilising the earth electrode resistance.

Highly swellable, powdery and extremely moisture retaining special clay provides a conductive earth electrode enclosure and reduces the soil resistivity.

Highly swellable, powdery and extremely moisture retaining special clay provides a conductive earth electrode enclosure and reduces the soil resistivity.

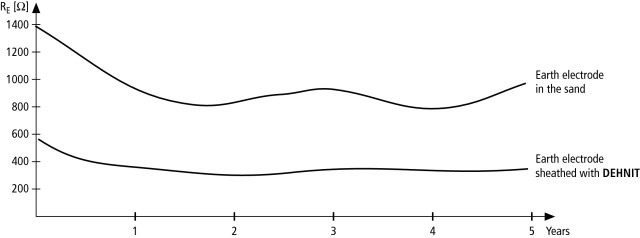

Figure 1

Principle of the DEHNIT earthing method is to bind the fine-grained DEHNIT with water and sand and to enclose the earth electrode with this mixture. This enclosure is onductive and thus it increases the earth electrode surface.

The DEHNIT enclosure method has three important benefits compared with the conventional earthing method:

– A low soil resistivity can be achieved even in case of a poor ground conductivity.

– The DEHNIT enclosure method reduces the soil resistivity by approx. 50 %, therefore lower costs for earth electrode material.

– The achieved soil resistivity is mostly independent of temperature and weather fluctuations and remain constant for years (see Figure 1).

The DEHNIT enclosure method has three important benefits compared with the conventional earthing method:

– A low soil resistivity can be achieved even in case of a poor ground conductivity.

– The DEHNIT enclosure method reduces the soil resistivity by approx. 50 %, therefore lower costs for earth electrode material.

– The achieved soil resistivity is mostly independent of temperature and weather fluctuations and remain constant for years (see Figure 1).

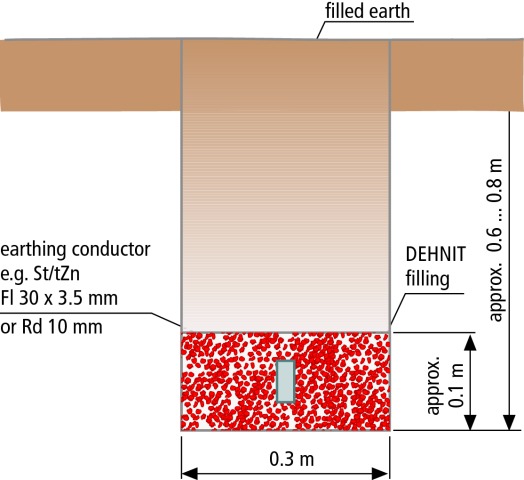

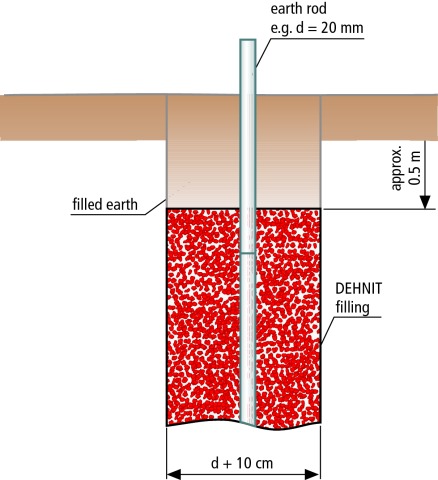

Figure 2 and Figure 3

Instructions for use:

Use approx. 100 kg DEHNIT for 1 m³ DEHNIT filling.

1. Surface earthing method

1.1 Dig the earth conductor trench (approx. 0.6 ... 0.8 m deep).

1.2 Mix DEHNIT (e.g. with a concrete mixer) as follows:

1 part of DEHNIT

5 parts of sand

1/2 part of water

Mind the indicated sequence to avoid clodding:

DEHNIT – sand – water

1.3 Fill the earth conductor trench with an approx. 5 cm high layer of this mixture.

1.4 Put the straightened earth conductor directly on this DEHNIT layer.

1.5 Cover the earth conductor completely with an approx. 5 cm thick layer of DEHNIT.

1.6 Compact/tamp the filling mechanically or by foot.

1.7 Refill the earth excavation.

1.8 Implement first resistance measuring of the earth-termination system.

Instructions for use:

According to this method 2 kg of DEHNIT per metre of earth conductor trench shall be used.

2. Method for earth rods

2.1 Bore as deep as the length of the earth electrode. Bore diameter at least 10 cm wider than outer diameter (d) of earth rod.

2.2 Mix DEHNIT according to 1.2.

2.3 Position earth rod centrally in the bore and refill with DEHNIT. Compact each 0.5 m of refill. Top layer of approx. 0.5 m shall be natural soil.

2.4 Implement first resistance measuring of the earth-termination system.

According to this method 0.84 kg of DEHNIT per metre of earth rod depth (d = 20 mm) shall be provided.

After a period of about three to four months the final earth electrode resistance is realised with a value of 1/2 – 1/3 measured immediately after filling the DEHNIT in.

Earth electrode resistance with DEHNIT earth-termination system is about 50 % lower than without DEHNIT enclosure. This resistance value remains constant for many years.

Use approx. 100 kg DEHNIT for 1 m³ DEHNIT filling.

1. Surface earthing method

1.1 Dig the earth conductor trench (approx. 0.6 ... 0.8 m deep).

1.2 Mix DEHNIT (e.g. with a concrete mixer) as follows:

1 part of DEHNIT

5 parts of sand

1/2 part of water

Mind the indicated sequence to avoid clodding:

DEHNIT – sand – water

1.3 Fill the earth conductor trench with an approx. 5 cm high layer of this mixture.

1.4 Put the straightened earth conductor directly on this DEHNIT layer.

1.5 Cover the earth conductor completely with an approx. 5 cm thick layer of DEHNIT.

1.6 Compact/tamp the filling mechanically or by foot.

1.7 Refill the earth excavation.

1.8 Implement first resistance measuring of the earth-termination system.

Instructions for use:

According to this method 2 kg of DEHNIT per metre of earth conductor trench shall be used.

2. Method for earth rods

2.1 Bore as deep as the length of the earth electrode. Bore diameter at least 10 cm wider than outer diameter (d) of earth rod.

2.2 Mix DEHNIT according to 1.2.

2.3 Position earth rod centrally in the bore and refill with DEHNIT. Compact each 0.5 m of refill. Top layer of approx. 0.5 m shall be natural soil.

2.4 Implement first resistance measuring of the earth-termination system.

According to this method 0.84 kg of DEHNIT per metre of earth rod depth (d = 20 mm) shall be provided.

After a period of about three to four months the final earth electrode resistance is realised with a value of 1/2 – 1/3 measured immediately after filling the DEHNIT in.

Earth electrode resistance with DEHNIT earth-termination system is about 50 % lower than without DEHNIT enclosure. This resistance value remains constant for many years.