Lightning and surge protection for the oil industry

Lightning strikes and transient overvoltages present a risk to the sensitive systems and components used in the oil industry. In today’s competitive environment system failure is a real threat. So, reduce cost-intensive operational disturbances and minimise down-time.

With a comprehensive lightning and surge protection concept you can optimise the continuous operation of oil pipelines, pump and slide gate valve stations, and storage tanks.

Protect oil pipelines

Prevent damage, keep interference voltage under control

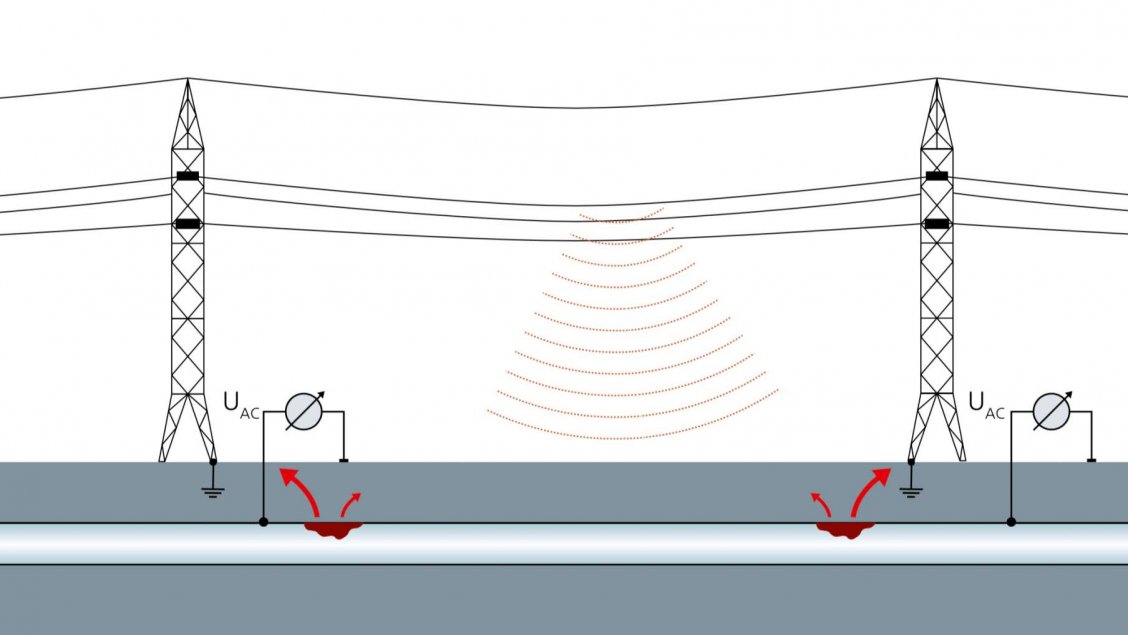

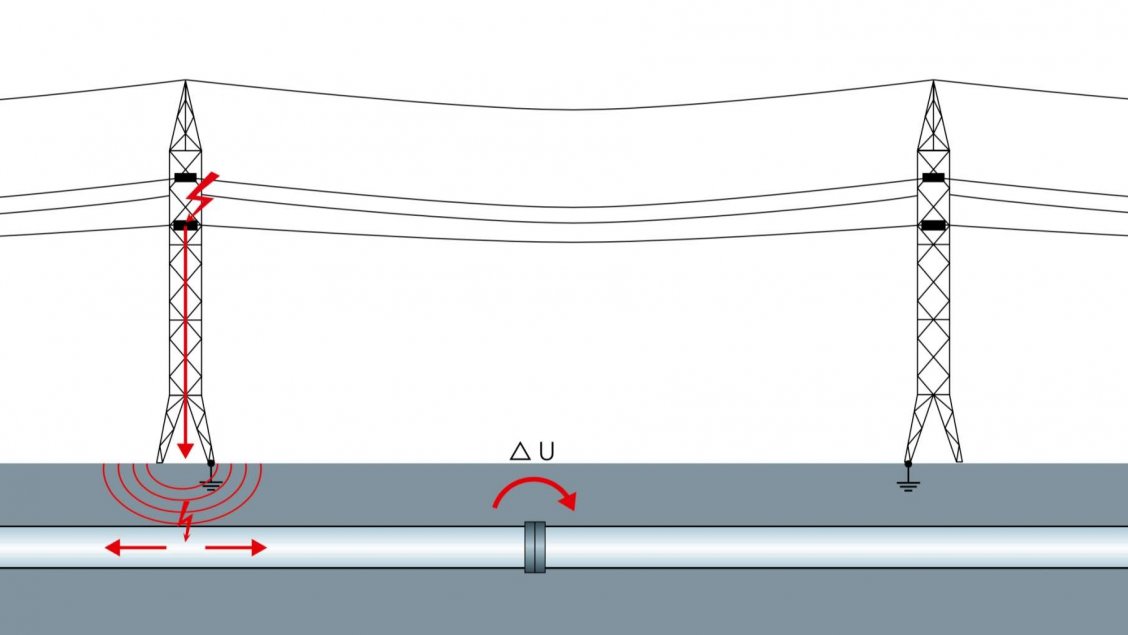

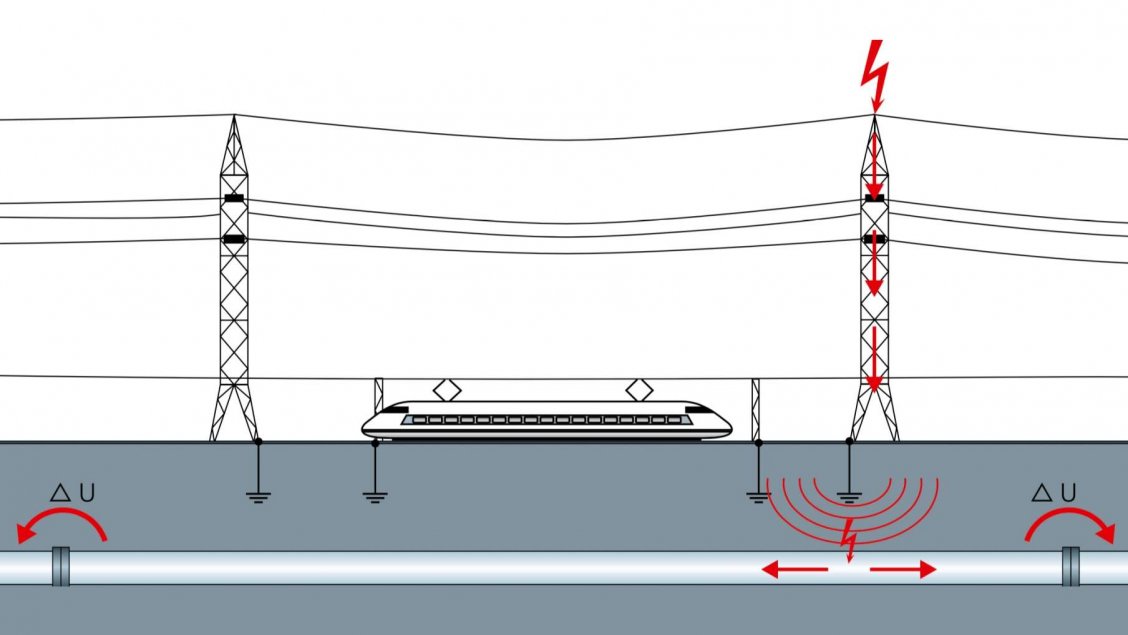

Pipelines often run alongside high-voltage lines or railway lines. If they run parallel, interference voltages can have a negative effect on pipelines causing wear and tear and thus corrosion damage.

Protect people

Interference voltages often lead to high touch voltages. These dangerous overvoltages present an enormous risk to people areas which are freely accessible and during maintenance work. The resulting injuries can be severe or even life-threatening. Don't let it come to this.

Influence of interference voltage

Interference voltage endangers human life and causes AC corrosion to components and devices.

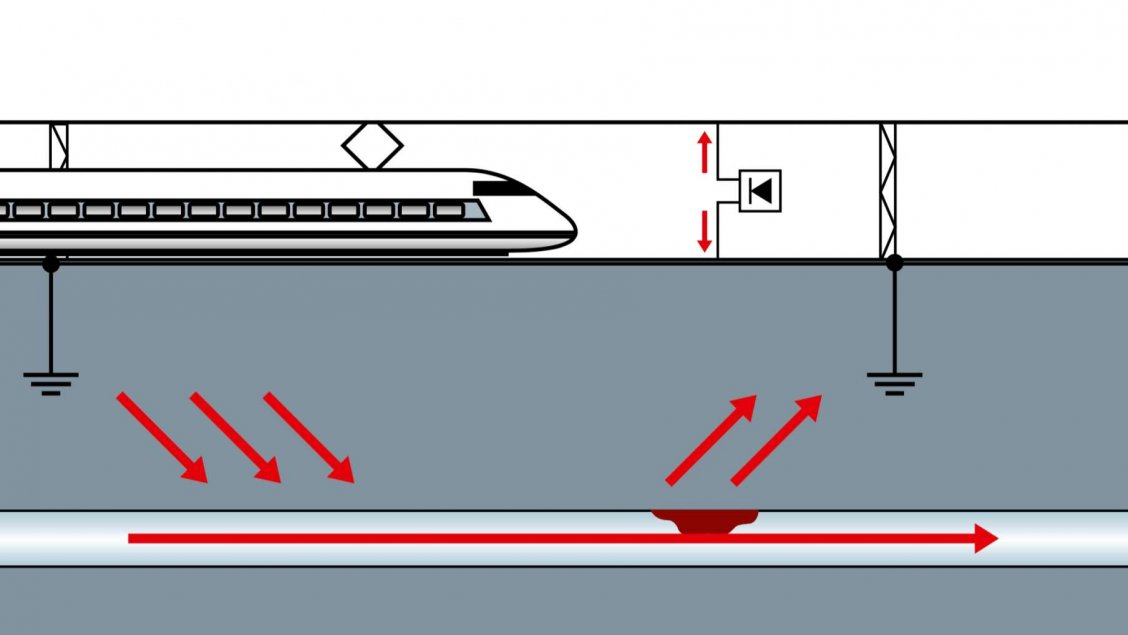

Sources of interference such as high-voltage lines, electric railways or lightning strikes produce stray currents and electromagnetic fields. These are injected into the pipeline via the ground, changing its potential and thus causing AC corrosion.

High costs due to leaks

This leads to leaks which often causes severe damage to property and the environment. The resulting costs are enormous: pipelines have to be repaired, there are supply bottlenecks and claims for damages due to leaked oil, etc.

| Interference voltage generated by a high-voltage line | Interference voltage from earth faults |

|  |

| Interference voltage caused by lightning strikes | Interference voltage from electric railways |

|  |

This is how you protect pipelines from damage

Passive corrosion protection

Passive corrosion protection, i.e. painting or coating the pipeline, is the first step. However, this alone does not suffice as even small imperfections in the coating soon lead to local corrosion on the pipeline. A far greater degree of safety is achieved with active corrosion protection.

Active corrosion protection

In the case of active corrosion protection, a protective current (direct current) prevents current from escaping in places where the coating or sheathing is flawed. This cathodic corrosion protection is the most effective method of permanently arresting electrochemical corrosion processes.

Contact us... xxx